- PET Board VS UV Sheet

- What do EVA, PUR, Laser, ABS, PVC Mean?

- China HPL sheets manufacturers & suppliers

- Where to Buy HDF Sheet?

- Particle board suppliers

Are you planning a home renovation or custom furniture project? Working with materials that offer both versatility and a flawless finish can make all the difference. While solid wood and plywood have their place, there’s one material that stands out for achieving perfectly smooth surfaces and intricate designs: MDF board. This engineered wood product has become essential for homeowners, carpenters, and DIY enthusiasts seeking professional results without the high cost of solid wood.

What is MDF Board?

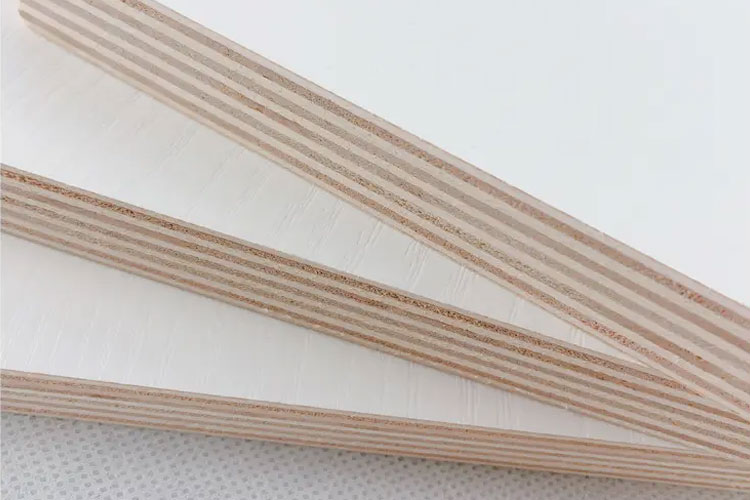

Medium-Density Fiberboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers. These fibers are combined with wax and a resin binder under high temperature and pressure to form dense, uniform panels.

Unlike plywood with its visible layers or particle board with its chunky composition, MDF features a completely smooth, consistent surface on both sides. This homogeneous structure makes it particularly suitable for applications requiring a clean, paintable finish or detailed machining.

Key Advantages of MDF Board

Understanding MDF’s unique benefits will help you determine when it’s the right choice for your project:

Perfectly Smooth Surface: MDF has no grain, knots, or voids, creating an ideal surface for painting and veneering

Excellent for Detailed Work: It machines beautifully, allowing for clean cuts, intricate routing, and detailed designs

Consistent & Uniform: The uniform composition provides consistent strength throughout the panel with no weak spots

Cost-Effective Alternative: More affordable than solid wood and high-quality plywood while offering better surface quality than particle board

Environmentally Friendly: Made primarily from recycled wood materials, making it a sustainable choice

Practical Considerations When Using MDF

While MDF offers numerous advantages, being aware of its limitations ensures project success:

Weight Considerations: MDF is denser and heavier than plywood or particle board of the same thickness

Moisture Sensitivity: Standard MDF isn’t waterproof and can swell if exposed to moisture (though moisture-resistant versions are available)

Dust Management: Cutting MDF produces fine dust particles, requiring proper ventilation and safety equipment

Edge Treatment: Raw edges need filling and sanding for a perfect finish when painting

Fastener Holding: Requires careful screw placement to prevent stripping; using appropriate fasteners is crucial

Common Applications of MDF Board

MDF’s unique characteristics make it ideal for various applications:

Painted Furniture & Cabinetry: Perfect for shaker-style cabinets, bookshelves, and furniture where a smooth painted finish is desired

Detailed Millwork: Excellent for decorative molding, wainscoting, and trim work thanks to its machining capabilities

Doors & Panels: Widely used for interior doors, cabinet fronts, and raised panel designs

Home Decor Projects: Ideal for picture frames, decorative wall panels, and custom shelving

Commercial Displays: Commonly used in retail displays, exhibition boards, and signage

MDF vs. Plywood vs. Particle Board

Understanding how MDF compares to other common materials helps in making informed decisions:

MDF vs. Plywood: MDF offers superior surface smoothness for painting, while plywood provides greater structural strength

MDF vs. Particle Board: MDF has higher density and durability compared to particle board, with better screw-holding capacity

Best Uses: Choose MDF for painted finishes and detailed work, plywood for structural applications, and particle board for budget-oriented projects where strength isn’t critical

Frequently Asked Questions

Q: Is MDF board suitable for kitchen cabinets?

A: Yes, MDF is excellent for cabinet doors and panels where a smooth painted finish is desired, though it’s not recommended for areas directly exposed to water.

Q: Can MDF be used for flooring?

A: Standard MDF isn’t suitable for flooring. Consider moisture-resistant MDF or specialized flooring materials for these applications.

Q: How do you seal MDF edges?

A: Use wood filler or dedicated MDF edge sealant, then sand smooth before painting for perfect results.

Q: Is MDF safe for home use?

A: Modern MDF produced in compliance with safety standards is safe for home use once sealed and painted, containing low formaldehyde levels.

Conclusion

MDF board offers an unbeatable combination of smooth surface quality, machining versatility, and cost-effectiveness for numerous woodworking and home improvement projects. Whether you’re building custom cabinets, creating detailed millwork, or crafting furniture that requires a flawless painted finish, MDF provides the consistent quality and workability needed for professional results.